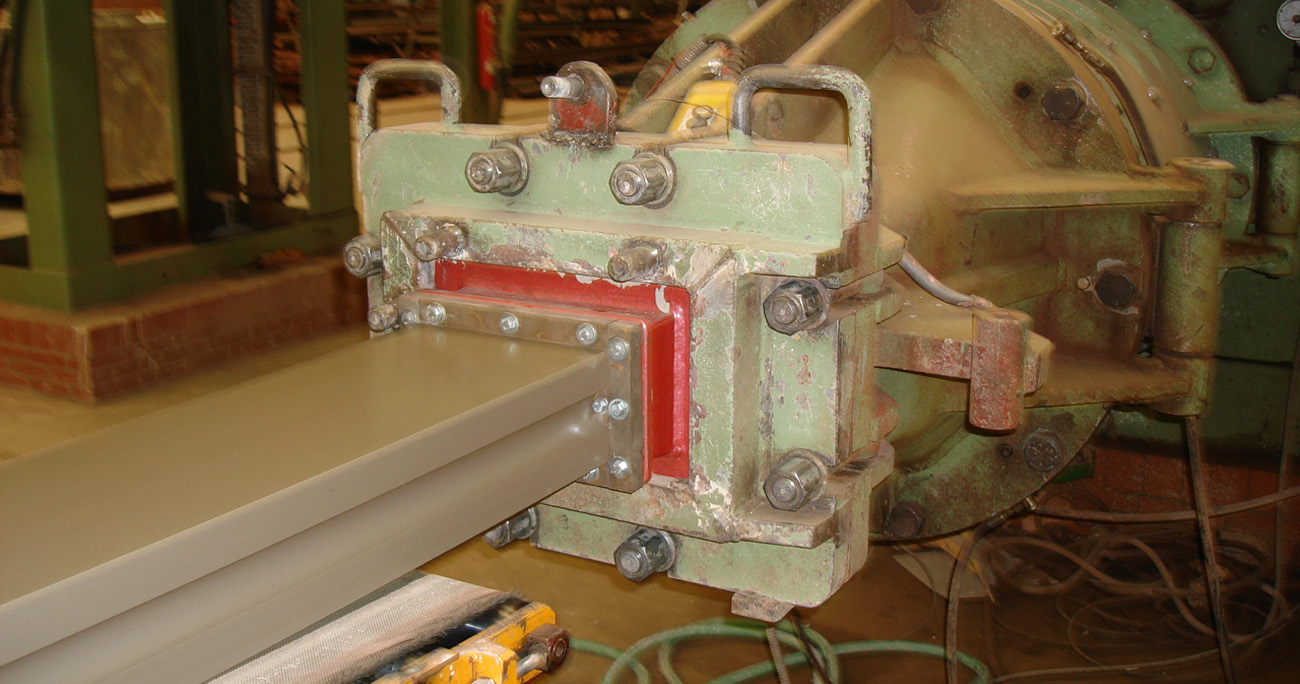

The extruder material (biscuit) output consists of a continuous clay bar of constant section. This section corresponds to the negative of the mold, that is, with the hollow part that remains between the frame (outer contour) and the studs (perforations of the piece). Subsequently, this continuous bar will be cut into individual pieces of the appropriate thickness.

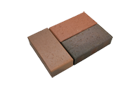

Through this type of process, bricks of various qualities can be manufactured, the KLINKER being the highest range. KLINKER quality bricks must meet the following three requirements:

– Water absorption less than 6%.

– Density greater than 2,000 kg/m³.

– Standardized compressive strength characteristic greater than 40 N/mm².

Facing Brick Advantages

Showing 1–12 of 53 results

-

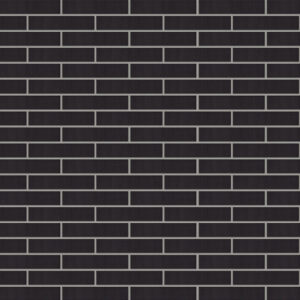

Black (5)

-

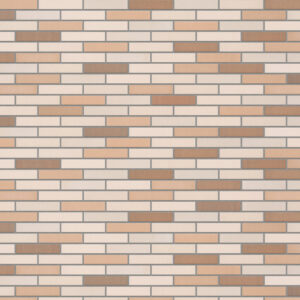

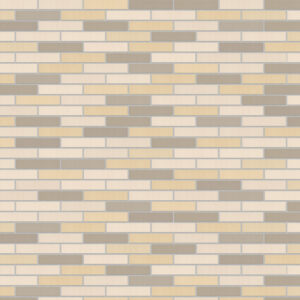

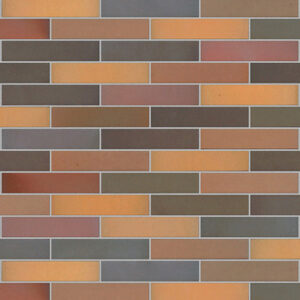

Blending (9)

-

Flashed (11)

-

Glazed (5)

-

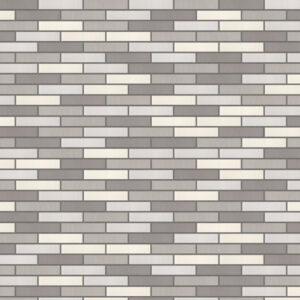

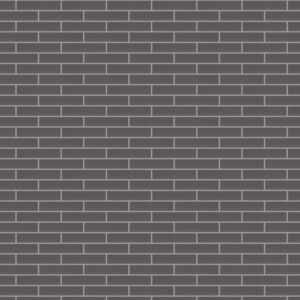

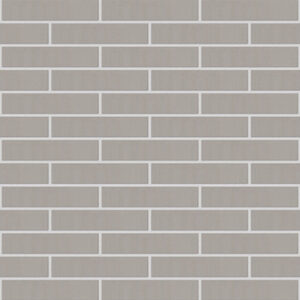

Grey (7)

-

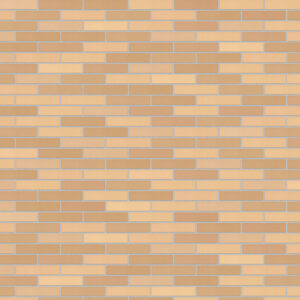

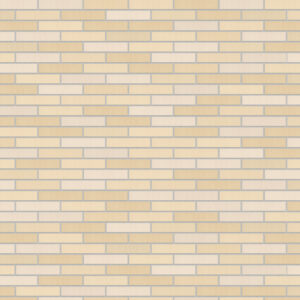

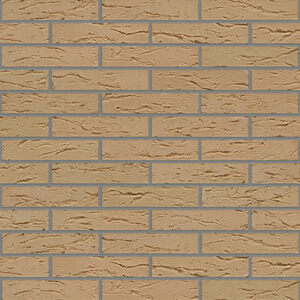

Light Colors (6)

-

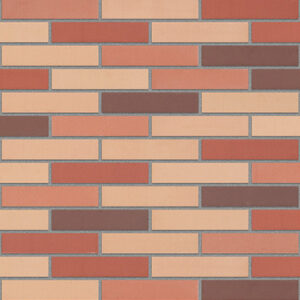

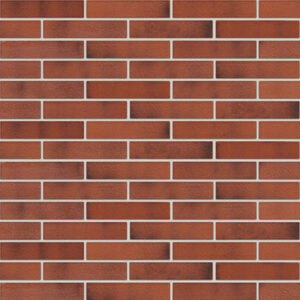

Red and Brown (4)

-

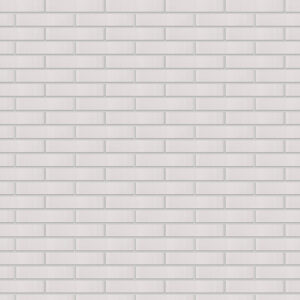

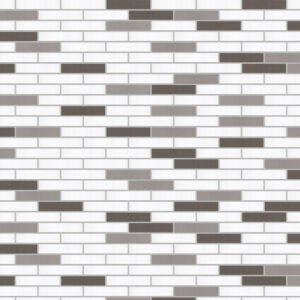

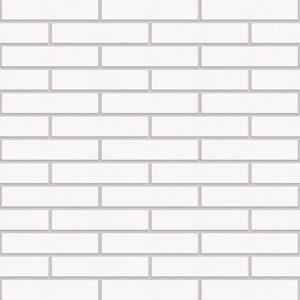

White (6)